| | Engraving | What is the IL REGALO forging method? | Inside setting | | ||||||||||||||||

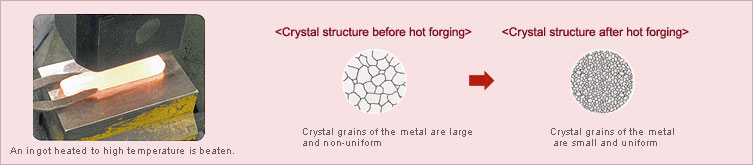

| The IL REGALO process begins by creating a cavity-free ingot using a special technique. That ingot is heated to high-temperature until it softens, and then it is beaten thin. Beating makes the large, non-uniform crystals of the metal into small, uniform crystals. This process is called "hot forging". |

|

|||||||||||||||

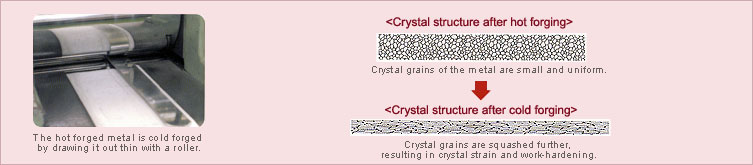

Next, the metal with uniform crystals is drawn into a thin sheet with a roller. This process is called cold forging, and it further squashes the small crystal grains. The squashed grains produce strain in the crystal, so work-hardening occurs. This makes the metal hard and strong.  *The forging process makes crystal grains in the metal smaller, and causes crystal strain and work-hardening, but the density of the metal does not change. There is no change in specific gravity or volume. < Vickers hardness >

|

||||||||||||||||

[Top] |

||||||||||||||||